- Home

-

Automotive & Safety

- Accessories & Supplies

- Auto & Motor Parts

- General Safety

- Alarm Systems & Accessories

- Anti-Slip Surfaces

- Child Safety

- Emergency & First Aid Kits

- Eyewear

- Face & Head Protection

- Fall Protection

- Fire Protection & Accessories

- Hearing Protection

- Home Testing Kits

- Knee Protection

- Marking Tapes & Flags

- Personal Safety

- Respiratory Protection

- Safety Clothing

- Smoke & Carbon Monoxide Detectors

- Safety Boot

-

Building & Plumbing

- Electrical

- Batteries & Flashlights

- Cable Reels & Wires

- Ceiling Fans & Accessories

- Circuit Breakers, Fuses & Load Centers

- Doorbells, Chimes & Accessories

- Electrical Boxes & Accessories

- Electrical Connectors, Tape & Terminals

- Extension Cords, Outlets & Accessories

- Interior Light Fixtures

- Light Bulbs & Accessories

- Light Fixture Parts

- Outdoor & Security Light Fixtures

- Portable Work Lights

- Electrical Switches & Sockets

- Home & Industrial

- Plumbing Supplies

- Building And Plumbing Supplies

- Electrical

-

Tools

- Power Tools

- Power Tools & Accessories

- Hand Tools

- Assembly Tools & Accessories

- Axes, Machetes & Shovels

- Chisels, Punches, & Nail Sets

- Concrete & Masonry Tools

- Drywall & Plastering Tools

- Electrical Tools

- Flooring Installation Tools

- Hammers & Screwdrivers

- Hand Saws & Accessories

- Workbenches, Sawhorses & Work Supports

- Spanners, Wrenches & Torque Wrenches

- Welding Machines

- Torque Wrenches & Multipliers

- Hand Tools & Accessories

- Tile Tools

- Tool Aprons, Trolley & Pouches

- Staple Guns & Brad Nailers

- Electrodes, Soldering & Welding Supplies

- Shaping & Marking Tools

- Pry & Wrecking Bars

- Nippers & Pliers

- Mechanic's Tools

- Material Handling

- Logging & Layout Tools

- Knives, Ratchet & Rivet Tools

- Sockets, Hex & Torx Keys

- Glazier & HVAC Tools

- Bricklaying Tools

-

Home & Outdoor

-

Bosch Hot!

Bosch Hot!

- Pros

- Skilled Professionals

- Architect

- Brick Mason & Brick Layer

- Building Surveyor

- Carpenter

- Civil Engineer

- Concrete Batcher & Block Moulders

- Concreter

- Construction & Building manager

- General Labourers

- Iron Bender (Steel fixer)

- Landscaper & Gardener

- Plasterer

- Plumber

- POP Installers

- Project Engineer

- Roofer

- Site Health and Safety Officer

- Site Engineer

- Stone Driller

- Structural Drafter

- Structural Engineer

- Tiller

- Welder

- Window and Glass Installer

- More Skilled Professionals

- Air Conditioning (AC) Repairer - Home & Industrial

- Air Conditioning (AC) Repairer - Car

- Electrician (House)

- Electrician (Car- Rewire)

- Home Decorator (Interior Designer)

- Mechanic Shop (General)

- Mechanic Shop (Japanese Car Specialist)

- Mechanic Shop (German Car Specialist)

- Mechanic Shop (American Car Specialist)

- Mechanic Shop (Tractors, Trucks and Heavy Duty Machines)

- Painter (House)

- Painter (Car)

- Panel Beater

- Repair Shop (Brush Cutter,Chainsaw & Lawn Mower)

- Skilled Professionals

Compare (0)

You have no items to compare.

Welcome to Mamtus Nigeria

Tools

Cold Chisel SDS Max 400 X 25

Product Description

COLD chisels are used to cut throughhard materials like metal or masonry. They are often used to cut or shape metal when the stock is thick and where other tools, like a hacksaw or tin snips, would be unsuitable.

Jigsaw 450 W M4301

450 W Top Handle Jig Saw, 3 Orbital Settings Plus Straight Cutting

- High performance and durability at less expense

- 3 orbital settings plus straight cutting with a powerful 450W motor for use in a variety of materials

- Variable speed control by trigger (0-3,100 SPM) enables user to match the speed to the application for optimal cutting performance in a variety of materials

- Through-the-body dust port provides optimal dust management with use of vacuum

- Bevel cuts to 45° right or left and positive stop at 90° for solid cutting performance

- Ergonomically designed rubberized grip for increased comfort and control

- Vacuum port enables direct connection of dust extractor

- Low noise level at only 82 dB(A) for improved user comfort

- Uses bayonet type blades

- Thick blades (of 1.7 mm thickness) can be attached

- Large 2-finger trigger switch with conveniently-located lock-on button for continuous use and increased operator comfort

- Onboard hex wrench for fast and easy blade changes and bevel adjustments

- Handy rip fence (guide rule) allows you to do extra-accurate straight cuts and circular cuts (country-specific)

- Double insulated

₦40,647.90Honda Engine GX 35

Engine features:

- The world's first 360° inclinable 4-stroke engine, for operation in any position

- The OHC design driven by a maintenance-free, low-noise timing belt, makes the engine more compact and light

- Easy starting, low noise, and superb acceleration

- High-quality materials and purpose-built components ensure reliable long-term use

- Meets the world's most stringent environmental legislation

- Low fuel and oil consumption

₦250,730.85Socket Wrench Insert 7-17mm

This EJOT socket wrench insert is for fastening all EJOT fasteners with hexagon head.

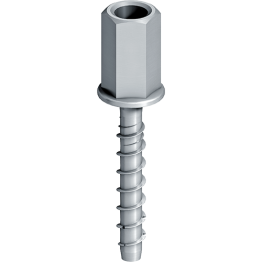

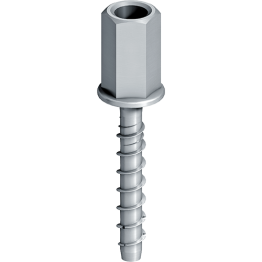

Concrete screw JC2-IT 6

- Approved for cracked concrete and non-cracked concrete

- Also suitable for pre-stressed hollow core slab, bricks and solid brick sandstone.

Self-drilling screw FD42

EJOT self-drilling screw is for fixing metal core and fittings to thickwalled and multi-ply PVC profiles and steel or aluminium reinforcements up to 4 mm thick.

Installation tool ECOset

- Up to 5 times higher fastening performance compared to conventional fastening solutions

- Fatigue-free working in upright position with consistently high installation performance

- Highest grade of reliability: EJOT Dabo® screw is always fastened at right angles to the roof surface

Installation tool ECOset HTK

For safe, fast and efficient installation of EJOT® HTK 2G stress plates with EJOT Dabo® screws TKR, TKE and VHT-R.

Drop-in Anchor LAL

Technical specifications

Characteristic values LAL+6/ LAL+8/ LAL+10/ LAL+12

- Inside diameter of thread: M6/ M8 /M10/ M12

- Nominal drill diameter d0: 8mm/ 10 mm/ 12 mm/ 15mm

- Effective Embedment depth hef: 25mm/30mm/ 40mm/ 50mm

- Max. installation depth Ls,max: 11 mm/ 13 mm/ 16 mm/ 23 mm

- Min. installation depth Ls,min:6 mm/ 8 mm/ 10 mm/ 12 mm

- Through hole diameter in the attached part df: 7 mm/ 9 mm/ 12 mm/ 14 mm

- Maximum Installation torque Tinst max: 4 Nm/ 8 Nm/ 15 Nm/ 35 Nm

LIEBIG step iron anchor

Used to attach step irons in wastewater revision chutes. The special plastic sleeves prevent bimetallic corrosion between the step iron and the anchor.